The subject of the offer is a novel, affordable and environmentally friendly method of synthesis of oxide catalysts with a high surface area, dispersed on aluminosilicate supports

Applications: removal of volatile organic compounds from stationary sources

Volatile Organic Compounds

It is estimated that around 60% of gaseous pollutants of Earth atmosphere are Volatile Organic Compounds (VOCs), which impact negatively human health by carcinogenic and mutagenic effects. Additionally, some VOCs participate in the formation of photochemical smog and influence the concentration of the stratospheric ozone. One of the methods of removal of VOCs is their catalytic oxidation in the presence of atmospheric oxygen. Nowadays, for these purposes, the catalysts based on precious metals and transition metals and their oxides deposited on a suitable porous support (eg. zeolites, SiO2, Al2O3) are utilized. An attractive alternative on the market of VOC oxidation catalysts could be highly effective materials based on natural clay materials that play the role of the supports for active phases in the form of metal oxides.

Technology

Aside from energy and chemical raw materials and metal ores, whose exploitation is carried out on a large scale, the natural minerals are nowadays widely used as economic catalytic supports. One of the groups of this type of materials are silicate and aluminosilicate layered minerals (so-called clay minerals), widely distributed in the form of easily accessible deposits in many places around the globe. Their catalytic properties can be easily enhanced by carrying out appropriate modifications, i.e. introduction of interlayer pillars by intercalation of the metal oligocations. The materials obtained in this way are characterized by a significantly developed of the specific surface, which enables to expose the catalytically active centers. The basic drawbacks of this synthesis path are, however, the limited possibilities of modifying the layered structure of aluminosilicate: only the oxides of these metals that form stable oligocations can be introduced into the structure of such materials.

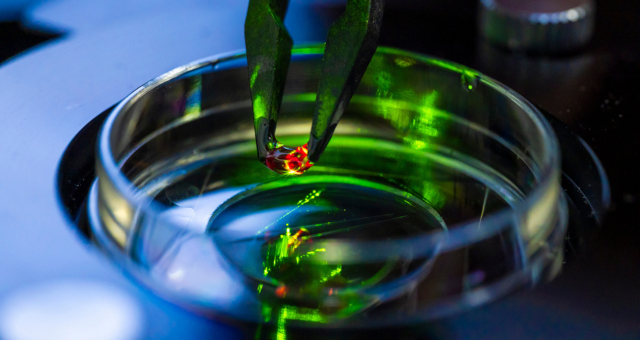

The solution to these issues is a new technique for the synthesis of catalysts produced on the basis of clay materials. The materials obtained through this innovative method can be used in all technologies requiring the use of catalysts having an acidic surface, on which the catalytically active phase is dispersed, e.g. in the processes of dehydrogenation and oxidation of hydrocarbons or - important from the point of view of environmental protection - reactions of reduction of nitrogen oxides as well as oxidation of volatile organic compounds.

Among other advantages of the invention, the following should be mentioned:

- reduction of costs and the adverse environmental impact due to lack of the use of expensive and toxic raw materials and reagents, including surfactants;

- tenfold development of the surface area compared to the starting material, which allows exposure of the maximum number of surface catalytic centers;

- improved availability of catalytic centers for reagents by maximum exposure of the oxide phase due to exfoliation of the aluminosilicate layered structure;

- the possibility of the shaping of the final composition of the catalyst produced by selecting the type and amount of metal introduced, a 10-fold increase of the surface area comparing to the starting material which allows to expose maximum number of active catalytic and adsorption centers;

The offered solution is subject to a patent protection in Poland, the United States and selected European countries. Further development of the invention is conducted at the Faculty of Chemistry of the Jagiellonian University. Currently the Centre for Technology Transfer CITTRU is looking for companies and institutions interested in licensing and application of the presented method

information / broker of Jagiellonian University