The subject of the offer relates to new oxide catalysts for the removal of nitrogen oxides, carbon particles and inorganic dusts from exhaust gases in the reactor designed particularly for this purpose. They can be applicable in CHPs (combined heat and power plants), nitric acid plants, waste incinerators, small to medium-sized boilers or diesel engines.

The most noxious gaseous air pollutants are nitrogen oxides, which are formed in all processes of combustion of solid, liquid or gaseous fuels. The annual emission of nitrogen oxides in Poland is about 860 000 tons and is increasing - in 2010 by about 5.4% compared to the year 2009 (according to data from the National Center for Emissions Management). The sources of the emission of nitrogen oxides to air are industries such as power and heat engineering, transport as well as all industrial processes, which are based on the chemical reactions used by chemical companies producing nitric acid and its derivatives and also fertilizers. Emission of the nitrogen oxides into the atmosphere in these processes is the major threat to the environment and has an influence on the formation of so-called photochemical smog, winter smog or acid rains.

Currently so-called DENOX technology is used for the removal of nitrogen oxides. The technology is based on the reduction of nitrogen oxides with ammonia, which is, however, relatively expensive and corrosive reducing agent and its use requires a costly dispensing devices. What is more, the conventional catalysts are deposited on the ceramic surfaces, which are relatively fragile and often undergo cracking and deformation. It may cause the mechanical damage of the surface of the catalyst responsible for its activity.

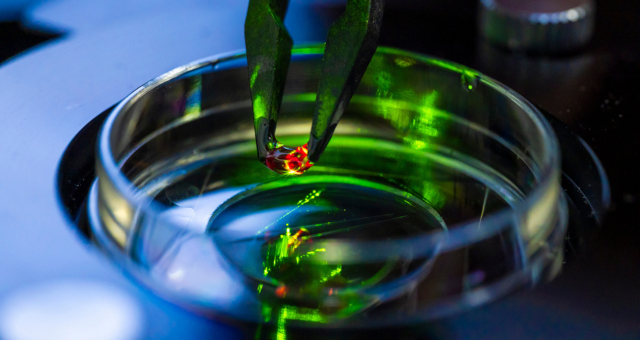

The subject of this offer relates to a process of preparing oxide catalyst for the direct decomposition of NO to N2 and 02. The offer includes also a reactor equipped with a catalyst for the direct decomposition of nitric oxide for the simultaneous removal of NO, carbon particles and the inorganic dust originating from the exhaust gases. The experiments carried out with the assistance of offered catalysts showed a high conversion efficiency of nitric oxide to nitrogen at relatively low temperatures - up to 93%. Designed reactor allows the direct removal of nitric oxide from the exhaust gases via the efficient decomposition of nitric oxide and, at the same time, systematic removal of carbon particles and other solid particles.

Other advantages of proposed solutions are:

- simple and inexpensive method for monolith formation allowing for easy application of the catalytic active carriers;

- no need for an additional reducing agent and thus dispensing system making the proposed process less expensive and more environmental friendly;

- stability of the catalytic parameters in time.

The catalysts can be successfully used in the processes of nitrogen oxides removing, for the formation of which are responsible: CHPs, nitric acid plants, waste incinerators, small to medium-sized boilers or diesel engines.

The proposed solutions are the subject of 6 patents and 13 patent applications. Further development of the inventions is under progress at Faculty of Chemistry of the Jagiellonian University. Currently the Centre for Innovation, Technology Transfer and University Development is looking for the entities interested in the cooperation and commercial applications of the described solutions.

information / broker of Jagiellonian University